Welcome to Flower Factory News & Updates

Stay up to date with our latest grow updates, cultivation tips, and industry news. Here you’ll find all our blog posts in one place

- Fine-Tuning Nutrient Strategies for Consistent Plant Health

2.5.26

As the growing year gains momentum, February is an excellent time to evaluate and refine nutrient management practices. While environmental control and sanitation form the foundation of successful cultivation, nutrient balance drives plant vigor, structural integrity, and overall productivity. Small adjustments to feeding strategies can have significant impacts on plant health, making this an ideal period to assess and optimize nutrient delivery.

Understanding the relationship between macronutrients and micronutrients is essential for maintaining balanced growth. Nitrogen supports vegetative development, phosphorus aids root formation and energy transfer, and potassium regulates water movement and stress tolerance. Meanwhile, secondary nutrients and trace elements such as calcium, magnesium, iron, and zinc play critical roles in cellular structure and metabolic processes. Ensuring these elements are present in appropriate ratios helps prevent deficiencies and toxicities that can compromise plant performance.

Monitoring electrical conductivity (EC) and pH levels provides valuable insight into nutrient availability. Even a well-formulated nutrient solution can become ineffective if pH drifts outside the optimal range, limiting uptake and leading to deficiency-like symptoms. Regular calibration of meters and consistent testing routines help maintain accuracy. Adjusting nutrient concentrations based on plant stage and observed uptake patterns ensures that feeding schedules remain aligned with plant needs rather than fixed assumptions.

Reservoir management is another key factor in nutrient stability. Stagnant solutions, temperature fluctuations, or biofilm accumulation can alter nutrient composition and promote microbial growth. Maintaining proper reservoir temperatures, ensuring adequate aeration, and performing routine solution changes help preserve nutrient integrity. Clean reservoirs support healthy root zones and reduce the likelihood of disease pressure.

Observing plant responses remains one of the most reliable diagnostic tools. Leaf coloration, growth rate, internodal spacing, and overall plant posture provide immediate feedback on nutrient effectiveness. Subtle signs such as tip burn, chlorosis, or leaf curling often indicate imbalances that can be corrected early with minor adjustments. Proactive observation prevents small issues from escalating into more serious deficiencies or toxicities.

Water quality should also be considered when refining nutrient strategies. Dissolved minerals, chlorine, or chloramine in source water can influence nutrient availability and microbial activity. Testing water sources and using filtration or conditioning methods when necessary helps create a more predictable baseline for nutrient formulation. Consistency in water quality supports repeatable results across growth cycles.

February’s focus on nutrient precision reinforces the broader goal of consistency. By monitoring EC and pH, maintaining clean reservoirs, observing plant feedback, and accounting for water quality, cultivators can fine-tune feeding strategies to support steady, healthy growth. Thoughtful nutrient management not only improves plant resilience and yield potential but also contributes to a more efficient and predictable cultivation process throughout the year.

- January 2026 – Establishing a Strong Foundation for the Growing Year

1.27.26

The start of a new year is an ideal time to focus on foundational practices that set the tone for consistent, high-quality cultivation. Success throughout the year often depends less on dramatic changes and more on refining core systems environmental stability, sanitation, workflow efficiency, and data tracking. Establishing strong fundamentals early reduces variability and helps ensure that each growth cycle builds upon the last.

Environmental control remains one of the most critical factors in cultivation. Stabilizing temperature and humidity within optimal ranges prevents plant stress and reduces the likelihood of pest and pathogen outbreaks. Calibrating sensors, verifying controller accuracy, and confirming proper airflow patterns can uncover small inconsistencies that might otherwise go unnoticed. Even minor adjustments to air circulation or dehumidification strategies can significantly improve plant health and uniformity across the canopy.

Sanitation protocols deserve renewed attention at the beginning of the year. Deep cleaning grow spaces, tools, irrigation lines, and reservoirs removes residual biofilm, algae, and potential pathogens that accumulate over time. Establishing a routine sanitation schedule including foot baths, tool sterilization, and controlled access to grow areas creates a cleaner environment that supports plant vigor and reduces risk throughout the year. Prevention remains far more effective than remediation.

Irrigation systems also benefit from early-year evaluation. Checking for clogged emitters, uneven distribution, or pressure inconsistencies ensures that plants receive uniform hydration. Testing runoff and monitoring moisture levels in the root zone help fine-tune watering frequency and volume. Consistent irrigation supports stable nutrient uptake and prevents common issues such as root rot, salt buildup, or drought stress.

Data collection and recordkeeping form the backbone of continuous improvement. Establishing or refining grow logs allows cultivators to track environmental conditions, feeding schedules, plant responses, and equipment performance. Over time, these records reveal trends that guide smarter decisions. A disciplined approach to documentation transforms anecdotal observations into actionable insights, enabling more precise adjustments and improved repeatability.

Lighting systems should also be reviewed to confirm efficiency and coverage. Cleaning fixtures, verifying timers, and ensuring even canopy distribution help maximize usable light. Evaluating whether current light intensity aligns with plant growth stages prevents wasted energy while promoting healthy development. Strategic lighting management contributes to uniform growth and improved overall plant structure.

Equally important is workflow optimization. Organizing tools, labeling storage areas, and refining daily routines reduce time spent on repetitive tasks and minimize the risk of cross-contamination. Efficient workflows allow more attention to be devoted to plant observation and proactive care two factors that often distinguish successful operations from struggling ones.

January is ultimately about preparation and precision. By reinforcing environmental stability, sanitation, irrigation reliability, and data-driven practices, cultivators create a resilient framework for the months ahead. A strong foundation supports healthier plants, smoother operations, and more predictable outcomes, ensuring that the year begins not with uncertainty, but with clarity, control, and confidence.

- December 2025 – Year-End Review: Refinement, Resilience, and the Path Forward

12.29.25

December provides an opportunity to step back and evaluate the full scope of the past year’s cultivation efforts. A comprehensive review of environmental controls, nutrient strategies, equipment performance, and plant outcomes reveals patterns that inform smarter decisions moving forward. Careful analysis transforms routine observations into actionable insights, allowing cultivators to refine their methods and build greater consistency into future cycles.

One of the most valuable exercises during this period is the review of grow logs and environmental data. Comparing temperature, humidity, vapor pressure deficit (VPD), and CO₂ levels across different growth stages highlights how small fluctuations can influence plant vigor and yield quality. Identifying periods of stress, whether caused by heat spikes, irrigation inconsistencies, or airflow limitations helps pinpoint opportunities for system improvements that reduce variability and promote stable growth conditions.

Lighting performance is another key area for reflection. Evaluating canopy penetration, light uniformity, and energy efficiency can reveal whether adjustments in fixture placement, spectrum selection, or photoperiod timing may enhance plant development. Even minor refinements, such as improving light distribution across the canopy, can contribute to more uniform growth and better overall plant structure.

Nutrient management also benefits from year-end analysis. Reviewing feeding schedules, runoff measurements, and plant responses can uncover imbalances that may have gone unnoticed during active cycles. Fine-tuning nutrient concentrations, adjusting pH targets, and monitoring electrical conductivity (EC) trends help prevent deficiencies and toxicities while promoting optimal uptake. A data-driven approach to nutrient planning supports healthier plants and more predictable outcomes.

Pest and pathogen management strategies deserve equal attention. Assessing which preventive measures were most effective, such as environmental controls, sanitation practices, or biological controls helps strengthen integrated pest management (IPM) protocols. Recognizing early warning signs and refining response strategies ensures faster intervention and minimizes crop risk in future cycles.

Infrastructure and workflow efficiency often emerge as overlooked factors that significantly impact productivity. Evaluating equipment reliability, workflow bottlenecks, and maintenance schedules can reveal opportunities to streamline operations. Upgrades such as improved environmental controllers, more efficient irrigation systems, or enhanced air filtration can reduce labor demands while improving consistency and plant health.

Equally important is planning for adaptability. Markets, regulations, and environmental conditions can shift, making flexibility a critical component of long-term success. Developing contingency plans for equipment failures, supply disruptions, or environmental extremes ensures resilience. A cultivation strategy built on adaptability allows growers to respond confidently to unexpected challenges without compromising plant quality.

As the year closes, thoughtful planning for the next cycle transforms reflection into progress. Setting measurable goals such as improving environmental stability, increasing energy efficiency, or enhancing canopy uniformity provides clear direction. Continuous improvement, guided by careful observation and data analysis, strengthens both operational efficiency and cultivation outcomes.

December is not merely an endpoint but a strategic pause, a time to refine processes, reinforce successful practices, and prepare for the opportunities ahead. By embracing a mindset of evaluation and incremental improvement, cultivators position themselves for sustained success, ensuring that each new cycle begins with greater knowledge, stronger systems, and renewed confidence in the path forward.

- Indoor System Maintenance and Planning for the Next Cycle

November 20th 2025

November is an ideal time for reflection and preparation within indoor cultivation systems. With the harvest complete and the grow space emptied, attention shifts to maintaining equipment, evaluating system performance, and planning for future cycles. Proper maintenance and strategic planning ensure that the next growth phase starts smoothly and efficiently, reducing downtime and optimizing productivity.

Cleaning and sanitizing the grow space is the first priority. Residual organic matter, dust, and nutrient buildup can harbor pests, mold, or pathogens if left unaddressed. Deep-cleaning surfaces, pots, trays, and tools with appropriate sanitizers eliminates potential sources of contamination. HVAC ducts, filters, and fans also benefit from thorough cleaning, which improves airflow, efficiency, and the overall environment for the next cycle.

Inspecting and servicing equipment prevents unexpected failures. Pumps, timers, humidifiers, dehumidifiers, lighting fixtures, and sensors should be tested and repaired as necessary. Replacing worn components, recalibrating sensors, and confirming the proper operation of automated systems reduces the likelihood of interruptions during the next growth phase. Preventive maintenance saves time and protects plant health in the long term.

Reviewing environmental data and performance logs offers insight into what worked well and what can be improved. Tracking temperature, humidity, CO2 levels, light intensity, and nutrient schedules from previous cycles highlights trends and identifies areas for optimization. Adjustments in environmental control strategies, light placement, or irrigation schedules can enhance efficiency and yield potential in future grows.

Planning the next cultivation cycle involves selecting strains, reviewing nutrient plans, and evaluating system capacity. Considerations such as expected flowering times, desired yield characteristics, and specific environmental requirements guide these decisions. Adjustments to canopy management strategies, training techniques, and pest management protocols can also be incorporated based on prior experience, ensuring continuous improvement.

Investing time in infrastructure upgrades during this off-season can provide long-term benefits. Whether improving airflow, adding supplemental lighting, upgrading hydroponic systems, or optimizing nutrient delivery, enhancements to the grow space contribute to healthier plants and higher-quality yields. Careful evaluation of energy efficiency and operational costs also supports sustainable practices, balancing productivity with resource management.

November is a period of preparation, reflection, and optimization. By thoroughly cleaning and maintaining equipment, analyzing system performance, and strategically planning the next cycle, cultivators establish a strong foundation for future success. Attention to these details ensures that the next indoor growth phase begins efficiently, with minimal stress to plants and maximum potential for high-quality, productive yields.

- Harvest Techniques and Post-Harvest Handling

October 2025

Harvest is the culmination of months of careful planning, monitoring, and cultivation. Proper timing and technique during this phase are essential to preserve potency, flavor, and overall quality. Post-harvest handling, including drying and curing, determines the final product’s stability, aroma, and smoothness.

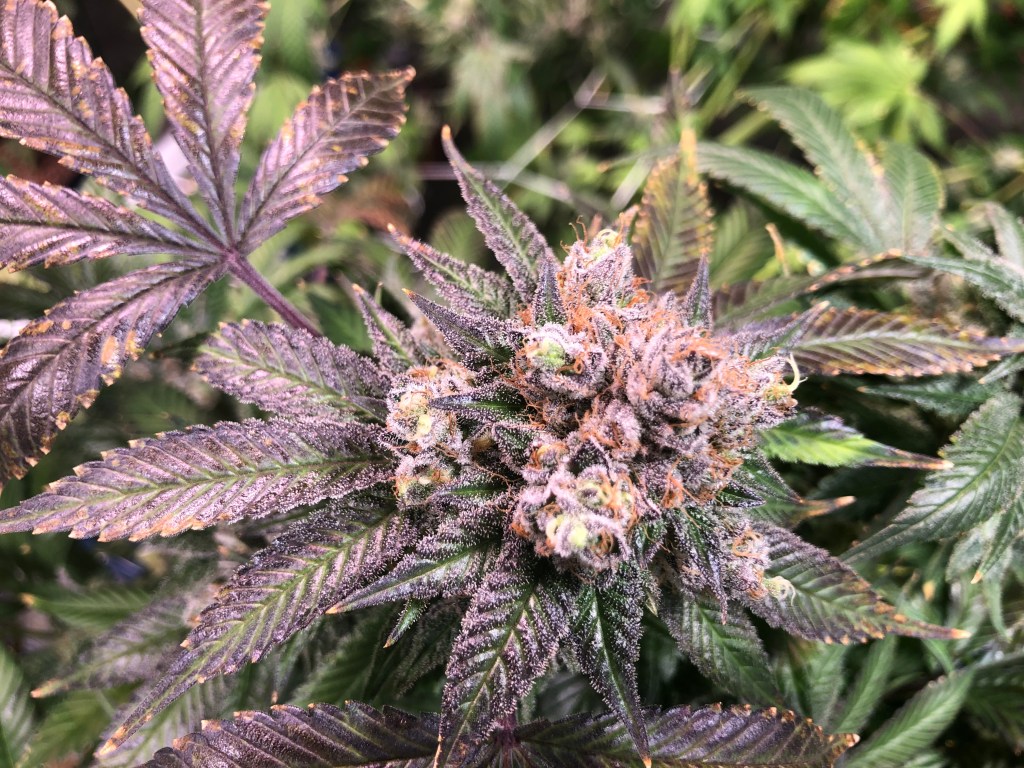

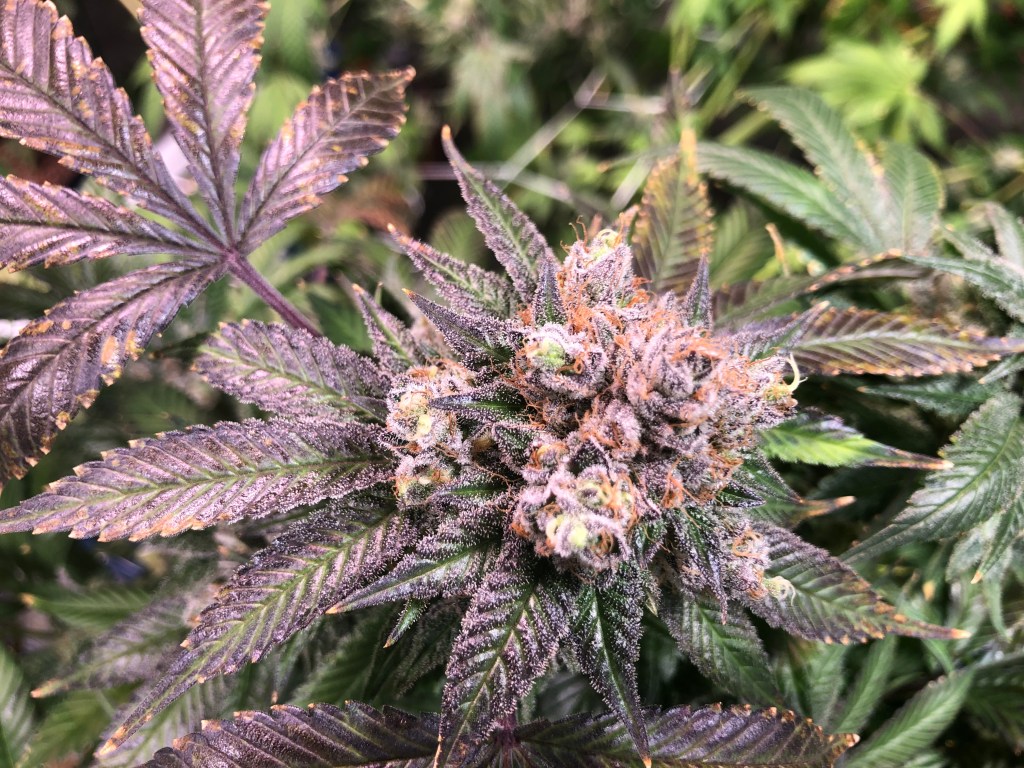

Timing the harvest is critical. Observing trichome development and pistil coloration provides the most accurate indicators of peak cannabinoid and terpene content. Harvesting too early can result in lower potency and underdeveloped flavor, while waiting too long may increase the risk of degradation, mold, or overripe characteristics. Careful inspection of multiple plants ensures that the entire crop is harvested at optimal maturity.

Proper cutting and handling techniques minimize damage. Using clean, sharp tools reduces stress on the plant and prevents microbial contamination. Buds should be handled gently to avoid bruising or breaking trichomes, which contain the majority of cannabinoids and aromatic compounds. Strategic trimming during harvest helps remove excess leaves and enhances airflow during the drying process.

Drying is the first step in post-harvest processing. Maintaining consistent temperature and humidity during drying prevents mold, mildew, and uneven curing. Ideal conditions typically involve moderate temperatures with controlled airflow and relative humidity around 50–60%. Hanging whole branches or using racks ensures proper circulation and even drying, preserving aroma, color, and potency.

Curing further enhances quality by allowing slow degradation of chlorophyll and redistribution of moisture within the buds. Proper curing techniques improve smoothness, flavor, and overall shelf stability. Regularly burping jars or containers helps release excess moisture and prevents mold formation, while maintaining a stable environment over several weeks enhances the final product’s characteristics.

Attention to detail during harvest and post-harvest handling transforms a well-cultivated crop into a premium product. By carefully monitoring maturity, using precise cutting techniques, controlling drying conditions, and implementing proper curing practices, cultivators preserve potency, flavor, and quality, ensuring that months of growth result in a rewarding and consistent yield.

- Final Flowering and Pre-Harvest Preparation

September 2025

As plants approach the final weeks of flowering, careful observation and fine-tuning are essential to maximize quality and yield. The pre-harvest period is a delicate phase where stress management, nutrient adjustments, and environmental control play a critical role in determining the potency, flavor, and overall success of the crop.

Trichome development becomes a primary indicator of readiness during the final flowering stage. Close inspection with magnification allows growers to monitor color changes—from clear to milky to amber—which signal peak cannabinoid and terpene content. Maintaining optimal light intensity and spectrum ensures that energy continues to support bud maturation without causing undue stress.

Environmental stability remains crucial. Slightly cooler night temperatures can enhance color development and slow excessive stretching, while humidity management prevents mold and bud rot in dense flowers. Gentle airflow ensures even drying potential within the canopy and minimizes localized moisture pockets that could lead to disease. Adjusting fans and ventilation strategically during this stage helps maintain a consistent microclimate around each bud.

Nutrient management shifts to support final maturation. Many cultivators reduce nitrogen and emphasize phosphorus and potassium to promote flower density and resin production. Flushing with plain water or light nutrient solutions in the last week or two before harvest can help remove excess salts from the root zone, which can improve taste and smoothness in the final product. Monitoring runoff pH and electrical conductivity ensures that nutrient adjustments are effective and safe for the plants.

Training and support systems are also important in the final flowering weeks. Buds can become heavy, stressing stems and causing breakage if not properly supported. Stakes, trellises, or netting help maintain canopy structure and prevent physical damage, ensuring that flowers develop fully without interruption.

Proper planning during the final flowering stage sets the stage for an efficient, high-quality harvest. By monitoring trichomes, maintaining stable environmental conditions, adjusting nutrient schedules, and supporting bud structure, cultivators can maximize potency, flavor, and yield. Attention to detail during this critical period ensures that all previous efforts culminate in a successful and rewarding harvest.

- Flowering Stage Optimization and Canopy Management

August 2025

The flowering stage is one of the most critical phases of cultivation, where plants shift energy from vegetative growth to bud development. Maximizing light penetration, airflow, and nutrient availability during this period is essential for producing dense, high-quality flowers and achieving consistent yields. Proper canopy management and environmental control set the stage for successful flowering.

Training and pruning techniques optimize light distribution and airflow within the canopy. Removing lower growth that receives little light, topping, and selective defoliation help focus energy on productive bud sites while reducing the risk of mold and pest infestations in shaded areas. Even canopy height ensures that all flowers receive sufficient light exposure, which promotes uniform development and improves overall quality. Techniques such as low-stress training (LST) or trellising can further enhance light penetration and increase the number of main colas.

Lighting strategy continues to play a major role during flowering. Red-spectrum light supports bud formation, while blue-spectrum light maintains compact growth and prevents excessive stretch. Maintaining consistent photoperiods—usually 12 hours of light and 12 hours of darkness for photoperiod-sensitive plants—triggers flowering while minimizing stress. Light leaks during the dark period can disrupt flowering signals and reduce yield, so attention to lightproofing and timer accuracy is critical.

Environmental control, including temperature and humidity, is vital to flower health. Slightly lower humidity reduces the risk of mold and mildew in dense buds, while moderate temperatures prevent heat stress that can damage trichomes or reduce terpene production. Air circulation, facilitated by fans and well-placed vents, maintains a steady environment and ensures that each bud site receives adequate airflow.

Nutrient management should be adjusted to support reproductive growth. Phosphorus and potassium play a more prominent role during flowering, while nitrogen levels are moderated to prevent excessive leafy growth. Monitoring plant response, runoff pH, and electrical conductivity allows fine-tuning of the nutrient regimen for optimal flower development. Foliar feeding or supplemental boosters can provide additional support if specific deficiencies are observed.

Thoughtful canopy management combined with precise environmental and nutrient control maximizes flowering potential. By observing plant development, adjusting training techniques, and maintaining stable conditions, cultivators ensure dense, healthy buds and a successful transition into the harvest period. Planning ahead during this stage directly impacts final quality, potency, and overall yield.

- Stress Management and Environmental Adjustments During Peak Summer Growth

July 2025

Summer brings unique challenges for indoor cultivation, as higher external temperatures can influence internal grow environments, affecting plant growth and health. Managing stress and maintaining stable conditions is crucial to prevent slowed development, nutrient imbalances, and reduced yields. A proactive approach ensures that plants remain resilient and productive even during seasonal fluctuations.

Temperature control is a primary factor during warmer months. Excessive heat can trigger plant stress, leading to leaf curling, slowed growth, or even damage to buds and foliage. Using HVAC systems, air conditioners, and strategically placed fans helps maintain a consistent temperature range appropriate for each growth stage. Automated climate controllers allow precise adjustments, ensuring that heat spikes are minimized and energy efficiency is maximized.

Humidity management is equally important. Elevated temperatures often increase transpiration rates, which can lead to rapid moisture loss if not balanced. Maintaining relative humidity within optimal ranges—typically 50–70% during vegetative growth and slightly lower during flowering—reduces stress and supports nutrient uptake. Dehumidifiers and proper ventilation help stabilize humidity, preventing mold, mildew, or pest outbreaks that thrive in high-humidity conditions.

Light and photoperiod considerations also play a role. Longer daylight exposure or high-intensity lighting combined with elevated temperatures can exacerbate stress. Adjusting light schedules, intensity, or distance from the canopy reduces heat stress while still providing adequate energy for photosynthesis. Reflective surfaces and light diffusers help distribute light evenly, minimizing hotspots and maximizing efficiency.

Nutrient management must be adapted during periods of stress. Plants experiencing heat or humidity fluctuations may require adjustments in watering frequency or nutrient concentrations. Overfeeding or underfeeding can worsen stress symptoms, so careful monitoring of plant response, runoff pH, and electrical conductivity is essential. Incremental adjustments help maintain balance without shocking the root system.

Implementing preventative and responsive measures—including proper ventilation, automated climate control, strategic lighting adjustments, and careful nutrient management—helps mitigate environmental stress during peak summer growth. By observing plant behavior, anticipating seasonal changes, and maintaining a stable internal environment, cultivators can ensure that growth remains vigorous and that yields meet expectations despite external conditions.

- Root Health and Media Optimization

June 2025

Strong roots are the foundation of vigorous growth and high-quality yields in indoor cultivation. Healthy roots absorb water, nutrients, and oxygen efficiently, supporting robust vegetative growth and productive flowering. Optimizing root health involves careful selection of growth media, maintaining ideal environmental conditions, and monitoring for stress or disease.

The choice of growing medium directly impacts root structure and function. Media such as coco coir, peat mixes, or hydroponic substrates each offer different water retention, aeration, and nutrient delivery characteristics. Selecting the right medium depends on the cultivation system, plant stage, and nutrient regimen. For hydroponic systems, substrates like rockwool or clay pellets provide excellent support and oxygenation, while soil-based media benefit from amendments like perlite or vermiculite to improve drainage and prevent compaction.

pH and moisture levels are crucial for optimal nutrient uptake. Roots can only absorb nutrients efficiently within specific pH ranges, typically 5.5–6.5 for most indoor systems. Overly acidic or alkaline conditions can cause deficiencies, even if nutrients are present in the solution. Maintaining consistent moisture without waterlogging the root zone prevents oxygen deprivation, reduces root rot risk, and encourages dense, fibrous root growth. Automated irrigation systems or careful hand-watering can provide the consistency required for healthy root development.

Aeration and oxygen availability are also essential. Roots require oxygen for respiration and nutrient metabolism. Hydroponic systems benefit from dissolved oxygen in nutrient solutions, while soil or coco-based systems can be improved with airflow around the root zone. Techniques such as air stones, oxygenated water, or substrate mixing enhance oxygen penetration and prevent anaerobic conditions that lead to root stress or disease.

Preventing and monitoring root-related issues ensures long-term plant vitality. Common problems include root rot, nutrient lockout, and fungal pathogens. Visual inspection of roots during transplanting or pruning, combined with periodic checks of moisture, temperature, and pH, allows for early detection of issues. Beneficial microbes and mycorrhizal inoculants can support root health, enhance nutrient absorption, and provide resistance against pathogens.

Optimizing root health and growth media is a critical component of any indoor cultivation strategy. By selecting the appropriate substrate, maintaining ideal moisture and pH, ensuring adequate oxygenation, and monitoring for stress, cultivators establish a strong foundation for robust plant development and consistent, high-quality yields throughout the growth cycle.

- Advanced Pest and Disease Prevention in Indoor Cultivation

May 2025

Maintaining a healthy indoor grow environment requires proactive strategies to prevent pests and diseases before they can impact plant health. Even minor infestations can quickly escalate in enclosed spaces, reducing yields, stunting growth, and compromising overall quality. Understanding the life cycles of common pests and identifying early signs of disease is essential for timely intervention and effective management.

Integrated Pest Management (IPM) is the foundation of advanced pest control. This approach combines monitoring, cultural practices, biological controls, and selective use of chemical treatments to maintain a balanced ecosystem while minimizing plant stress. Regular inspection of leaves, stems, and roots allows for early detection of spider mites, thrips, aphids, and other common indoor pests. Sticky traps, magnification tools, and systematic scouting schedules ensure that infestations are caught before they spread.

Biological controls offer a sustainable alternative to chemical pesticides. Introducing predatory insects such as ladybugs, predatory mites, or beneficial nematodes can help regulate pest populations naturally. These organisms coexist with the plants and target specific pests without causing harm to the crop, supporting long-term ecosystem health within the grow environment.

Environmental management is another key preventative measure. Maintaining appropriate temperature, humidity, and airflow limits conditions that favor pest and pathogen proliferation. Overly humid environments encourage mold and mildew, while stagnant air allows pests to concentrate in hidden areas. Optimizing HVAC systems and using oscillating fans promotes air circulation, reduces hotspots, and discourages fungal and insect activity.

Sanitation practices further strengthen plant defenses. Regular cleaning of tools, trays, and workspaces, combined with removing dead or decaying plant material, reduces breeding grounds for pests and pathogens. Quarantining new plants before introducing them into the main grow space prevents accidental introduction of pests or disease.

In cases where intervention is necessary, selective treatments should be used carefully to minimize plant stress and prevent resistance. Organic and low-toxicity options, such as neem oil, insecticidal soaps, and beneficial microbial sprays, are preferred for routine management. Combining these with cultural and biological controls creates a robust, multi-layered defense system.

By integrating monitoring, environmental control, biological solutions, and sanitation practices, indoor cultivators can maintain healthy, resilient crops while minimizing the risk of infestation or disease. A proactive and systematic approach ensures that pest and disease issues are addressed efficiently, protecting both yield and quality throughout the growth cycle.

- Light Spectrum and Advanced Indoor Lighting Strategies

April 2025

Lighting is one of the most influential factors in indoor cultivation, impacting photosynthesis, growth rate, plant morphology, and ultimately yield quality. Understanding light spectrum and intensity allows for precise control over plant development, whether in vegetative growth or flowering stages. Different wavelengths of light trigger distinct physiological responses, and tailoring lighting strategies can optimize every aspect of plant performance.

Blue light (400–500 nm) promotes compact growth, strong stems, and leaf development. It is particularly effective during the vegetative stage, encouraging robust branching and dense canopy formation. Red light (620–700 nm), on the other hand, is crucial for flowering and bud development, stimulating photosynthetic activity and reproductive growth. Full-spectrum LED systems combine these wavelengths and additional ranges to provide a balanced light environment, closely simulating natural sunlight.

Light intensity is equally important. Photosynthetically active radiation (PAR) levels should be monitored to ensure that plants receive sufficient energy for growth without risk of light stress or bleaching. Canopy height and spacing must be adjusted to avoid hot spots or uneven light distribution, as areas receiving less light can lag in growth, reducing uniformity and overall yield. Reflective materials and strategic placement of supplemental lighting help maximize efficiency.

Photoperiod management works hand-in-hand with spectrum control. Longer light periods favor vegetative growth, while shorter periods trigger flowering in photoperiod-sensitive plants. Some cultivators also experiment with extended red light exposure to enhance flowering characteristics, but this requires careful observation to prevent stretch or stress. Dimming capabilities, programmable schedules, and automated timers allow precise control over light cycles and intensity.

Efficiency and sustainability are additional considerations. Modern LED systems consume significantly less power than traditional HID lighting while generating less heat, reducing the load on HVAC systems. Heat management strategies, such as proper ventilation and placement of lights, maintain stable canopy temperatures, minimizing environmental stress. Regular maintenance, including cleaning lenses and checking connections, ensures consistent light output and reduces variability between cycles.

Incorporating a thoughtful lighting strategy based on spectrum, intensity, and photoperiod control maximizes plant health, encourages vigorous growth, and enhances flowering quality. By combining observation with experimentation, cultivators can fine-tune lighting setups to meet the specific needs of each strain and stage of growth, creating an environment that supports high yields and superior quality year-round.

- Optimizing Airflow and HVAC for Indoor Cultivation

March 2025

Air circulation and climate control are critical components of a successful indoor grow environment. Proper airflow ensures that plants receive a consistent supply of fresh air, prevents stagnant pockets that can harbor pests or mold, and helps maintain uniform temperature and humidity throughout the canopy. Without effective ventilation, even minor imbalances can lead to stress, reduced growth, and lower yields.

Designing an HVAC system for indoor cultivation involves more than simply installing fans or vents. The goal is to create a stable environment where temperature, humidity, and air movement are balanced and predictable. Intake and exhaust systems should be positioned to promote even distribution of air, avoiding dead zones where hot or humid air can accumulate. Oscillating fans and ducting can help ensure that all areas of the grow space receive consistent airflow, supporting healthy transpiration and gas exchange.

Temperature management is closely linked to airflow. Consistent temperatures promote steady growth, while fluctuations can stress plants, slow nutrient uptake, or trigger unwanted flowering behaviors. Typically, vegetative stages thrive in slightly warmer conditions, while flowering stages benefit from a cooler environment to encourage resin development and slow excessive stretch. Strategic placement of intake, exhaust, and oscillating fans can help maintain these optimal ranges throughout the canopy.

Humidity control is equally important. Excessive humidity increases the risk of mold, mildew, and other pathogens, while overly dry air can stress plants and reduce transpiration efficiency. HVAC systems that incorporate dehumidifiers or humidity controls allow precise regulation, while continuous monitoring ensures that environmental conditions remain within the ideal ranges for each stage of growth.

Energy efficiency should also be considered. Well-designed HVAC and airflow systems reduce energy costs while maintaining a stable environment. Variable speed fans, properly insulated ducting, and smart controllers can optimize airflow and climate regulation, allowing for minimal waste and maximum control over the growing environment.

By prioritizing airflow and HVAC design, indoor cultivators create conditions that support consistent growth, prevent common environmental stressors, and maximize overall plant health. Thoughtful planning, monitoring, and maintenance of these systems provide the foundation for successful cultivation cycles and contribute to higher yields and superior quality.

- CO₂ Optimization for Indoor Growth

February 2025

Carbon dioxide (CO₂) is a fundamental component of photosynthesis, and optimizing its levels can significantly enhance plant growth and yield in indoor cultivation. While ambient air typically contains around 400 ppm of CO₂, increasing this concentration to 1,000–1,500 ppm during the vegetative and early flowering stages can accelerate photosynthetic activity and encourage more vigorous development.

Effective CO₂ enrichment requires careful monitoring and control. CO₂ levels that are too high can stress plants, while levels that fluctuate excessively reduce the benefits. CO₂ generators, compressed gas systems, or natural supplementation methods can be used, but they should always be paired with accurate digital sensors to maintain target concentrations. Proper distribution within the grow space is essential; CO₂ is heavier than air, so elevated or evenly circulated placement ensures that plants receive consistent exposure.

Environmental factors such as temperature, humidity, and lighting interact with CO₂ availability. Optimal enrichment is most effective when temperatures are slightly elevated within the plant’s comfort zone and when lighting intensity is sufficient to support increased photosynthesis. Humidity should also be managed carefully, as high humidity can limit transpiration and reduce the plant’s ability to utilize CO₂ efficiently.

Timing of CO₂ enrichment is another important consideration. Concentrations should be elevated primarily during the photoperiod when lights are on, as plants are actively photosynthesizing. During the dark period, CO₂ supplementation is unnecessary and can lead to wasted resources. Automated timers and controllers simplify this process, ensuring precise delivery and minimizing manual oversight.

Safety is a crucial factor in CO₂ management. Enclosed grow spaces require adequate ventilation to prevent dangerous accumulation of CO₂ in areas accessible to humans. CO₂ sensors with alarms can help protect anyone entering the space. Regular maintenance of enrichment equipment also reduces the risk of leaks or equipment failure.

Incorporating CO₂ optimization as part of a comprehensive indoor growth strategy can dramatically improve plant vigor, canopy density, and overall yields. By carefully monitoring levels, controlling distribution, and adjusting for environmental conditions, indoor cultivators can leverage this critical resource to support more robust and productive cultivation cycles.

- Advanced Nutrient Techniques for Indoor Cultivation

January 2025

Optimizing nutrients is one of the most critical steps in achieving robust growth and high-quality yields in indoor cultivation. Beyond the basic macronutrients — nitrogen, phosphorus, and potassium — plants require secondary nutrients like calcium, magnesium, and sulfur, as well as trace micronutrients including iron, manganese, zinc, copper, and boron. These elements play essential roles in photosynthesis, enzyme function, and overall plant metabolism, and deficiencies or imbalances can quickly stunt growth or reduce yield quality.

Foliar feeding is a valuable tool to deliver micronutrients directly to leaves for rapid correction of deficiencies. Spraying a diluted nutrient solution can quickly alleviate visible symptoms, but it must be done carefully to avoid leaf burn or over-saturation. In hydroponic systems, monitoring the electrical conductivity (EC) of the solution ensures that nutrient concentrations remain within optimal ranges, as overfeeding can lead to nutrient lockout, while underfeeding can produce subtle deficiencies over time.

Adjusting nutrient ratios based on the growth stage is another critical consideration. During the vegetative stage, a higher nitrogen concentration encourages leaf and stem development, while during flowering, phosphorus and potassium levels should be emphasized to promote robust bud formation. Careful observation of plant response allows for incremental changes without overcorrecting. Maintaining accurate records of nutrient schedules, solution compositions, and plant reactions provides valuable data for optimizing future cycles and ensuring consistency across batches.

Environmental factors also affect nutrient uptake. Root temperature, pH levels, and oxygenation all influence how effectively plants absorb and utilize nutrients. Keeping the root zone slightly cooler in hydroponic systems can improve oxygen retention, while maintaining pH within the ideal range (typically 5.5–6.5) ensures micronutrients remain bioavailable. Balancing these variables requires diligence but pays dividends in overall plant health and productivity.

Finally, using high-quality, well-formulated nutrient products reduces the risk of imbalances, while supplementing with organic additives such as humic acids, kelp extracts, or beneficial microbes can enhance nutrient availability and root health. A systematic approach that combines careful monitoring, stage-specific nutrient ratios, and attention to environmental conditions forms the foundation for advanced nutrient management and sets the stage for a successful and productive indoor cultivation cycle.

- Year-End Review: Lessons Learned and Planning Ahead

December 2024

As 2024 comes to a close, it’s the perfect time to take a step back and assess the successes and challenges of the year. Maintaining detailed grow logs throughout the year has proven invaluable, allowing us to analyze everything from lighting schedules and nutrient formulations to pest management techniques and overall plant health. Looking back, we can see which lighting setups yielded the most robust vegetative growth, which nutrient ratios produced the densest buds, and which ventilation and airflow strategies effectively prevented mold and mildew outbreaks.

One key takeaway from this year is the importance of regular monitoring and minor adjustments. Small changes in pH, EC levels, or light intensity at the right stage can have a dramatic impact on plant development. Documenting these adjustments and their results has given us a clearer picture of how to optimize indoor growth cycles moving forward. Similarly, the proactive pest management strategies implemented earlier in the year significantly reduced infestations, proving the value of integrating beneficial insects, sticky traps, and careful environmental control.

Another area of focus this year was hydroponic system maintenance and efficiency. By reviewing water temperatures, nutrient delivery schedules, and system cleanliness, we were able to minimize root stress and maximize nutrient uptake. These lessons will guide future setups, ensuring that next year’s cycles are even more productive and consistent.

Beyond the technical aspects of growing, reflecting on operational practices is equally important. This includes evaluating strain selection, timing for vegetative and flowering stages, and planning for outdoor cycles where applicable. Strains that performed particularly well under controlled conditions are candidates for repeat cultivation, while underperforming varieties offer lessons in both genetics and environmental management.

Looking ahead to 2025, careful planning will allow for smoother, more efficient operations. Equipment upgrades, from lighting to climate control, are on the agenda, as well as potential refinements to our hydroponic setups and grow space layout. The year-end review also highlights the importance of preparing for unexpected challenges, whether they be environmental, technical, or pest-related. By analyzing successes and setbacks in tandem, we can make informed decisions that improve both yield and quality.

Ultimately, the practice of taking a comprehensive look at each year’s cultivation cycle ensures continuous improvement and positions the business for sustainable success. From careful documentation to incremental system upgrades and refined growing techniques, the lessons learned in 2024 provide a strong foundation for another productive year of cultivation, ensuring that every plant reaches its full potential and that the business continues to build on its reputation for quality and expertise.

- Post-Harvest Curing for Maximum Quality

November 2024

Curing buds after drying is essential to preserve flavor, smoothness, and potency. Store buds in airtight containers and burp them daily to release moisture and maintain even drying. Maintaining a consistent, slightly cool environment prevents mold and ensures terpene retention. Attention to curing transforms harvested flowers into high-quality final product.

- Harvest Preparation and Early Drying Techniques

October 2024

Harvesting at the right time ensures optimal potency and flavor. Monitoring trichome development helps determine the ideal window. Gentle trimming and careful handling prevent damage to buds. For drying, maintain a cool, dark environment with good airflow to avoid mold. Patience during this stage pays off, as proper drying preserves aroma and cannabinoid content.

- Hydroponic System Maintenance Before Harvest

September 2024

As flowering peaks, hydroponic systems require close attention. Flushing with clean water before harvest can improve final flavor and quality, while removing algae and debris ensures roots remain healthy until the end. Checking pumps, reservoirs, and tubing for clogs or leaks reduces the risk of last-minute failures. Careful system maintenance during this critical stage helps maximize final yield and quality.

- Managing Pests During Peak Growth

August 2024

Even well-maintained indoor grows can experience pest issues during high-density growth periods. Regular monitoring with sticky traps and leaf inspections is key. Beneficial organisms, such as predatory mites or nematodes, provide preventative control. Cleanliness, proper pruning, and quarantining new plants reduce risk. Addressing infestations promptly ensures that plants continue developing without stress, maintaining healthy yields.

- Optimizing Lighting Schedules for Yield

July 2024

Understanding photoperiods is critical for controlling growth stages. Vegetative plants generally thrive under 18–24 hours of light, while flowering plants require a strict 12-hour light/dark cycle. Using timers ensures consistency, which reduces stress and promotes predictable growth. Combining intensity management with spectrum adjustments helps optimize photosynthesis and flower development. Regularly observing plant response allows minor tweaks for ideal results.

- Nutrient Management for Strong Growth

June 2024

Balanced nutrition is essential for vigorous growth. In hydroponic systems, following a reliable nutrient schedule and monitoring EC ensures plants receive the right mix of macro- and micronutrients. Foliar feeding can supplement deficiencies, but should be used sparingly. Adjusting nutrient ratios as plants move from vegetative to flowering stages maximizes development. Tracking plant response allows fine-tuning without risking overfeeding or nutrient lockout.

Screenshot - Preventing Mold and Mildew in Flowering Plants

May 2024

As plants enter the flowering stage, high humidity can increase the risk of mold and mildew. Keeping relative humidity around 40–50% and maintaining good airflow within the canopy are key preventative measures. Dehumidifiers and proper ventilation help, but regular inspections remain essential. Trimming lower leaves and removing debris from the grow space further reduces infection points. A proactive approach ensures healthy buds and avoids losses during harvest.

- Understanding Different Types of Grow Lights

April 2024

Lighting is one of the most important factors for indoor cultivation. LED lights have become the go-to for energy efficiency and spectrum control, while traditional HPS and MH lights are still popular for flowering and vegetative phases. Understanding the light spectrum and intensity can make a significant difference in yield and quality. Positioning lights at the correct distance from the canopy, adjusting according to plant growth stages, and combining supplemental lighting when needed ensures even coverage and reduces light stress.

- Dialing in Hydroponics for Maximum Efficiency

March 2024

Hydroponic systems offer rapid growth but require careful monitoring. Maintaining the correct pH (usually 5.5–6.5) and electrical conductivity (EC) ensures nutrients are available and prevents deficiencies. Regularly flushing and cleaning the system helps avoid algae buildup and root rot. Different hydroponic styles, from NFT channels to deep water culture, have unique considerations, so understanding water flow, oxygenation, and nutrient timing is crucial. Keeping detailed logs allows growers to adjust and optimize feeding schedules for peak performance.

- Dealing with Common Indoor Pests

February 2024

Indoor grows are not immune to pests, and early detection is essential. Spider mites, fungus gnats, and aphids are the most common indoor offenders. Regularly inspecting leaves, especially under the canopy, helps catch infestations early. Beneficial insects, like predatory mites, can provide a natural solution, while neem oil or insecticidal soaps work for minor outbreaks. Keeping the grow room clean, avoiding standing water, and quarantining new plants before introducing them helps prevent problems. An integrated pest management approach ensures healthy crops without relying on harsh chemicals.

- Optimizing Indoor Climate for Healthy Growth

January 2024

As we start the new year, maintaining a consistent indoor climate is key for healthy plants. Temperature, humidity, and airflow all play a role in preventing stress and promoting strong growth. Keeping daytime temperatures around 70–78°F and nighttime temperatures slightly cooler helps balance growth and respiration. Using oscillating fans and proper venting ensures good air circulation, reducing the risk of mold and mildew. For hydroponic setups, monitoring nutrient solution temperature is equally critical, as it affects root health and nutrient uptake. Consistent climate control sets the foundation for a productive year.

- Title: 5 Tips for First-Time Medical Marijuana Patients in Oklahoma January 2024

Starting your medical marijuana journey can feel overwhelming at first, but Oklahoma’s patient-friendly program makes the process easier than many expect. Here are five tips for first-timers:

- Get Your Card – Apply online with the OMMA (Oklahoma Medical Marijuana Authority). You’ll need a physician recommendation and proof of residency.

- Start Low and Go Slow – Dosage varies widely by individual. Begin with a small amount and monitor your response.

- Ask Questions – Dispensary staff are trained to guide patients through strain selection and product options.

- Explore Different Methods – Smoking flower is just one option. Tinctures, edibles, and topicals may be better suited to your lifestyle.

- Keep Records – Track what products work best for you so you can fine-tune your care plan.

- Finding Relief During the Holidays: How Medical Marijuana Supports Wellness – Dec. 2023

The holiday season can be one of the most joyful times of the year, but for many patients, it also brings unique challenges. Stress, anxiety, disrupted sleep, and even seasonal pain flare-ups can make December a difficult month to manage. Fortunately, medical marijuana has become a valuable tool for patients looking to maintain balance and wellness throughout the holidays.

1. Managing Stress and Anxiety

Between family gatherings, shopping, and travel, stress levels tend to rise this time of year. Many Oklahoma patients turn to calming strains rich in CBD or balanced hybrids that promote relaxation without heavy sedation.2. Supporting Sleep

Late nights and busy schedules can disrupt sleep patterns. Indica-leaning strains or infused tinctures can help patients unwind and achieve the rest their bodies need.3. Easing Chronic Pain

Cold weather and increased activity often make conditions like arthritis and back pain more noticeable. Topicals and tinctures infused with THC and CBD can provide targeted relief.4. Promoting Mindful Celebration

Medical marijuana doesn’t have to be about symptom relief alone. For many patients, it’s also about improving overall quality of life. Used responsibly, it can enhance mindfulness, allowing patients to be more present and engaged with loved ones during holiday festivities.Closing Thoughts

As Oklahoma’s medical marijuana program continues to mature, patients have more options than ever to find products that support their health and lifestyle. This December, remember that wellness is a gift worth prioritizing — and medical marijuana can play an important role in keeping the season both joyful and manageable.

- Winter Indoor Growth and Year-End Planning

December 2023

December is dedicated to maintaining indoor flowering during winter and planning for the next year. Temperature and humidity are carefully controlled, and CO₂ remains at 1,200–1,400 PPM to maximize growth. Small experimental batches of new strains are grown to evaluate vigor, resin, and flavor for 2024. Equipment inspections and preventative maintenance are completed to avoid downtime, and operational reviews are conducted to refine processes for next year. By the end of December, indoor crops are healthy, curing is ongoing for the outdoor harvest, and Flower Factory is ready to begin a new cycle of production in the coming year.

- Curing and Indoor Flowering

November 2023

November focuses on curing outdoor harvests and supporting indoor flowering. Outdoor buds are burped daily to maintain proper humidity, while indoor crops reach late-flower stages under 12/12 light cycles. CO₂, nutrient feedings, and airflow are all carefully managed to maximize bud density and quality. HVAC systems, fans, and dehumidifiers are inspected and maintained to prevent any interruptions in the indoor environment. Lessons from the outdoor harvest guide adjustments for indoor operations, ensuring a consistent high-quality yield.

- Medical Marijuana in Oklahoma: Five Years of Growth and Patient Impact – Nov. 2023

In June 2018, Oklahoma voters approved State Question 788, officially launching the state’s medical marijuana program. Now, more than five years later, the program has grown into one of the most open and fastest-moving markets in the United States.

With over 400,000 active patient licenses and thousands of dispensaries across the state, access has never been easier. But beyond the numbers, what has this meant for Oklahomans?

1. Expanded Patient Access

Unlike other states with limited qualifying conditions, Oklahoma allows physicians to recommend medical marijuana for a wide variety of patient needs. This flexibility has empowered patients to explore cannabis as an alternative or complement to traditional medicine.2. Local Economic Impact

The medical marijuana industry has created jobs, boosted local economies, and provided tax revenue that supports state services. Dispensaries, growers, and processors have become a staple in both urban and rural communities.3. Variety and Innovation

From traditional flower to edibles, tinctures, concentrates, and topicals, the Oklahoma market continues to diversify. Patients now have access to products that meet their lifestyle and medical needs in more personalized ways than ever before.4. Community and Education

Dispensaries and advocacy groups have worked hard to educate patients on responsible use, proper dosing, and product safety. This community-driven approach has made a difference in patient confidence and care.Looking Ahead

As the program continues to evolve, one thing is clear: medical marijuana is here to stay in Oklahoma. With ongoing improvements in regulation, testing, and patient education, the future looks promising for patients and providers alike.

- Outdoor Harvest

October 2023

October is harvest month for the outdoor crop, with plants carefully hand-trimmed and hung in drying rooms maintained at 60–65°F and 50–55% humidity. The slow drying process preserves terpenes, flavor, and potency. Indoor crops continue flowering, with nutrient adjustments and lighting schedules optimized to finish strong. Outdoor greenhouses and equipment are cleaned and sanitized as buds are moved into curing jars. Curing is done gradually, with humidity monitored to stabilize at 62%, ensuring maximum aroma and smoothness. October is the culmination of months of planning and care, marking the successful end of the outdoor cycle.

- Pre-Harvest Care

September 2023

September is a transition month as outdoor plants begin forming their buds while indoor crops reach mid-flower. Outdoor plants receive careful nutrient adjustments to shift toward bloom support, emphasizing phosphorus and potassium while reducing nitrogen. Irrigation is closely monitored to prevent overwatering, which can dilute flavor and potency. Indoors, flowering plants are monitored for trichome development and bud density, with lighting, CO₂, and humidity fine-tuned for optimal resin production. Pest prevention continues for both indoor and outdoor crops, and airflow is checked constantly to prevent mold or mildew. September is about preparing the outdoor crop for harvest while keeping indoor flowers on track for peak quality.

- Outdoor Growth and Indoor Flowering

August 2023

August is the peak vegetative period for the outdoor crop, with plants rapidly developing stems, leaves, and canopy structure. Irrigation schedules are closely monitored, and nutrients are adjusted to ensure balanced growth, emphasizing nitrogen for healthy foliage. Indoors, flowering plants continue under precise 12/12 light cycles with CO₂ and VPD carefully managed to encourage bud site development. Lower branches are pruned to improve airflow and light penetration, and pest management remains constant with sticky traps, beneficial insects, and regular inspections. This month is critical for maintaining both the outdoor crop’s health and the indoor flower’s quality.

- Outdoor Planting Begins

July 2023

July marks the beginning of the single outdoor crop for the year, while indoor crops transition into early flowering. In the greenhouse, healthy clones and seedlings are planted into prepared soil, with careful attention to spacing, irrigation, and sunlight exposure. Nutrient schedules are designed to support early vegetative growth while preventing stress in young plants. Indoors, flowering plants are on a 12/12 light cycle, with CO₂ enrichment maintained at 1,200–1,400 PPM and temperature and humidity carefully controlled. Fans and ventilation are monitored to prevent hotspots and maintain even airflow. July is all about establishing a strong outdoor foundation while keeping indoor crops on track for a productive flowering period.

- Indoor Flower Prep

June 2023

June is the final month of indoor vegetative growth before flowering begins. Plants are given their final stretch of vegetative light cycles, with CO₂ and temperature carefully maintained to optimize leaf expansion and stem thickness. Pruning and low-stress training continue to ensure an even canopy, and nutrient levels are fine-tuned to maintain steady growth without inducing stress. Equipment checks are conducted on HVAC systems, fans, and dehumidifiers, ensuring all indoor rooms are ready for the flowering cycle. This month is also spent reviewing strain selections for the outdoor crop, finalizing planting plans, and ensuring all greenhouses and outdoor equipment are ready for July.

- Indoor Canopy Management

May 2023

May is dedicated to ongoing indoor canopy management and preparation for the upcoming outdoor planting. Plants are pruned strategically, with low or overlapping branches removed to improve airflow and light penetration. CO₂ enrichment remains at 1,200–1,400 PPM, and temperature and humidity are kept in a stable range to prevent stress. Nutrient schedules are adjusted based on plant development, with attention paid to micronutrients to ensure vibrant leaf coloration and strong root systems. Pest prevention is emphasized with sticky traps and careful monitoring, and any sign of early infestation is treated promptly. By carefully managing the indoor environment, we set the stage for robust flowering later in the year.

- Fine-Tuning Indoor Growth

April 2023

April continues the focus on indoor growth, with all energy directed toward strengthening plants and expanding canopy coverage. Supplemental lighting and reflective surfaces are optimized to ensure even light distribution across every branch, while CO₂ levels remain consistent to maximize photosynthesis efficiency. Nutrients are carefully balanced to maintain vigorous vegetative growth without pushing excessive stretch, and lower leaves are monitored to prevent signs of early nutrient or water stress. Fans and ventilation are adjusted regularly to maintain airflow, preventing microclimates where pests or mold could take hold. By the end of April, indoor plants are healthy, strong, and ready for flowering in the coming months.

- Indoor Vegetative Optimization

March 2023

March is focused entirely on indoor vegetative growth as we prepare our plants for strong flowering later in the year. Plants are under 18/6 light cycles with CO₂ maintained around 1,200–1,400 PPM and temperatures carefully regulated between 74–78°F during lights-on and 66–70°F at night. Nutrient schedules emphasize nitrogen to promote robust leaf and stem development, while pruning and low-stress training help shape the canopy for maximum future light penetration. Airflow and humidity are constantly monitored to prevent early pest or mold problems, and any minor deficiencies are addressed immediately. This month is about building a healthy foundation that will pay off in both indoor flower yield and overall plant vigor.

- Plant Health and Pest Prevention

February 2023

February is all about maintaining plant health and preventing early infestations. Spider mites, aphids, and fungus gnats are monitored with sticky traps and occasional beneficial insects. Indoor humidity is kept between 50–55% to reduce mold risk, and lighting schedules remain steady. Nutrient adjustments continue to support steady vegetative growth, preparing plants for an early spring transition outdoors.

- Indoor Growth and Environmental Optimization

January 2023

January focuses on indoor vegetative growth and fine-tuning our environment for maximum efficiency. Plants are under 18/6 light cycles, with CO₂ maintained at 1,200–1,400 PPM and temperature around 74–78°F during lights-on. Fans and ventilation systems are adjusted to prevent stagnant airflow, and nutrients are balanced to promote strong stems and healthy leaves. This month is about ensuring plants enter the new year strong and ready for flowering later.

- Winter Indoor Growth and Year-End Reflection

December 2022

December is dedicated to maximizing indoor growth under winter conditions and planning for the year ahead. Cold outdoor temperatures make climate control essential, so HVAC systems, dehumidifiers, and fans are carefully monitored to maintain stable temperatures and humidity. Indoor plants continue flowering with CO₂ maintained at 1,200–1,400 PPM, and day/night temperatures are carefully balanced to keep growth consistent. Small experimental batches of new strains are grown to evaluate vigor, resin production, and flavor profiles for 2023. Equipment inspections and maintenance are completed to prevent downtime, and lessons from 2022 — including outdoor harvest techniques and indoor yield improvements — are reviewed to inform future operations. By the end of December, indoor crops are thriving, outdoor harvests are curing beautifully, and Flower Factory is poised for another year of high-quality flower production.

- Curing, Indoor Finishing, and Maintenance

November 2022

November focuses on curing the outdoor harvests and keeping indoor crops thriving. Outdoor buds are jarred and burped daily, maintaining relative humidity around 62% to ensure a slow cure that enhances aroma, smoothness, and shelf life. Inside, flowering plants are in mid- to late-stage, and we closely monitor trichome development while adjusting nutrient feedings for final ripening. Lighting schedules are fine-tuned to maximize bud density. At the same time, HVAC units, fans, dehumidifiers, and other equipment are serviced to maintain a clean, stable environment and prevent winter pest outbreaks. With the indoor operation ongoing, strain selection for 2023 trials is finalized and nutrient and CO₂ plans are reviewed. November is a critical month to preserve the work of the outdoor harvest while ensuring indoor crops continue to flourish.

- Harvest Season

October 2022

October is peak harvest month for the outdoor crop, while indoor flowering continues to push forward. Outdoor plants are carefully hand-trimmed and hung in controlled drying rooms, where temperatures are kept around 60–65°F and humidity at 50–55% for slow drying. This process preserves terpenes and maximizes flavor. While some plants are drying, the team cleans greenhouses, sterilizes tools, and checks irrigation lines, making sure everything is ready for the next cycle. Indoor crops continue under 12/12 light cycles with CO₂ enrichment maintained at 1,200–1,500 PPM and VPD carefully monitored to maximize resin production. Lower growth is pruned for better airflow, and pest and mold management remains a constant focus. Fans are adjusted to prevent stagnant air, and sticky traps are rotated weekly. By keeping both indoor and outdoor operations tightly managed, Flower Factory maintains steady year-round production and high-quality flower.

- September 2022 – Flower Initiation & Bud Site Development

September 2022

September brings the start of flowering indoors and outdoors. For the outdoor crop, the days shorten and plants naturally transition into bloom. Indoors, we’ve flipped to 12/12 light cycles. This is when pre-flowers become clusters of developing bud sites, and nutrient needs shift — lower nitrogen, higher phosphorus and potassium. We’re also scouting heavily for pests like spider mites, which love this transitional stage.

- August 2022 – Dialing in Indoor Environments During Late Veg

August 2022

As summer peaks, our indoor rooms stay in late vegetative growth. The focus this month is airflow, lighting schedules, and canopy management. We’ve added supplemental CO₂ to hit 1,200–1,400 PPM for optimal growth, and we’re monitoring VPD (vapor pressure deficit) carefully to balance humidity and temperature. Healthy veg now means fewer problems down the line when flowering kicks in.

- Outdoor Planting Begins; Indoor Growth Maintains Momentum

July 10, 2022

July marks the start of Flower Factory’s outdoor cycle, while indoor crops continue thriving under controlled conditions.

- Outdoor Tips: Greenhouse #2 is fully planted, soil pH 6.0–6.5, drip irrigation in place, partial shade cloth installed for peak sun protection.

- Indoor Focus: Vegetative growth continues with LST, CO₂ enrichment at 1,200–1,500 ppm, and careful nutrient monitoring.

- Pest Management: Beneficial insects are deployed outdoors, while indoor scouting prevents mite or gnats outbreaks.

Both indoor and outdoor crops are monitored daily for maximum health and productivity.

- Fine-Tuning Environmental Controls

June 15, 2022

June is focused on maximizing indoor plant performance as growth accelerates.

- Temperature & Humidity: Daytime 74–78°F, nighttime 66–70°F; humidity kept at 55–60% to reduce mold risk.

- CO₂ Management: Maintained at 1,200 ppm during lights-on to enhance photosynthesis.

- Training: Continued LST and minor defoliation improve canopy airflow and bud site exposure.

By keeping environmental conditions stable, we ensure consistent growth across all indoor strains.

- Nutrient Adjustments and Indoor Health Checks

May 12, 2022

Indoor plants are thriving, and May is the perfect time to fine-tune nutrient schedules and monitor overall plant health.

- Nutrients: Balanced feedings with 20-10-20 NPK for vegetative growth; minor tweaks based on leaf color and growth rate.

- Airflow: Oscillating fans and HVAC adjustments prevent hotspots and reduce humidity-related risks.

- Early Strain Trials: Small batches of new hybrids are being tested indoors for vigor and yield potential.

Regular inspections ensure plants remain healthy and ready for the next stage of growth.

- Optimizing Indoor Vegetative Growth

April 10, 2022

Spring indoor cycles are in full swing at Flower Factory. Our main focus this month is vegetative growth: ensuring strong stems, healthy foliage, and efficient nutrient uptake.

- Lighting: Plants receive 18/6 light cycles with full-spectrum LEDs for optimal photosynthesis.

- CO₂: Levels are maintained at 1,000–1,200 ppm to encourage robust leaf development.

- Pruning & LST: Low-stress training opens the canopy, increasing airflow and light penetration.

- Pest Management: Sticky traps and weekly scouting help prevent fungus gnats and spider mites.

April is all about giving indoor plants a strong foundation for the months ahead.

- Spring Growth Preparations

March 12, 2022

With spring approaching, Flower Factory is preparing for our next growth cycles. Indoor plants are thriving under optimized light and nutrient schedules, and greenhouse spaces are being prepped for outdoor planting.

Our team is also experimenting with minor tweaks to pruning techniques and training methods, aiming to maximize bud structure and cannabinoid profiles. These preparations will ensure robust growth throughout the warmer months.

- Winter Maintenance and Indoor Enhancements

February 15, 2022

February has been focused on maintenance and indoor enhancements. Our team performed inspections of lighting, climate systems, and irrigation to ensure everything is operating efficiently.

This month also saw adjustments to our nutrient schedules and airflow systems, improving overall plant health. The refinements we’re making now will directly impact spring growth and set the stage for a successful year ahead.

- Starting 2022 Strong at Flower Factory

January 12, 2022

The new year is off to a strong start at Flower Factory! Our team is reviewing last year’s harvest data and refining strategies for 2022. Indoor plants are being prepared for the winter growth cycle, with careful attention to light, temperature, and humidity.

We’re also planning upcoming hybrid strain trials and evaluating new cultivation techniques to improve both yield and quality. Patient safety and consistency remain our top priorities, and we’re excited to share regular updates throughout the year.

- Wrapping Up 2021: A Year of Expansion and Growth

December 20, 2021

2021 has been a landmark year for Flower Factory. The indoor expansion increased capacity by 50%, and the addition of a second greenhouse allowed us to cultivate a larger outdoor crop than ever before.

From careful pruning to precise nutrient schedules, our team worked diligently to maintain plant health and quality. The year ends with strong lab results, high patient satisfaction, and valuable insights that will guide our cultivation strategies in 2022.

- Post-Harvest Review and Fall Planning

November 15, 2021

With the harvest complete, Flower Factory is reviewing growth data and refining techniques for the coming season. Lab testing confirms the quality and potency of all batches, giving patients reliable and consistent flower.

We’re also preparing the greenhouses and indoor spaces for winter cycles, adjusting light schedules and environmental controls. This analysis helps us optimize future growth and improve both yield and product quality.

- Fall Harvest in Full Swing

October 15, 2021

Harvest season has arrived! Flower Factory’s indoor and greenhouse crops are being carefully harvested to preserve potency, flavor, and aroma.

Our team is focused on precise trimming, curing, and lab testing to ensure every batch meets our high standards. The combination of the indoor expansion and two greenhouses has allowed us to maximize yield without compromising quality.

Photos and updates from the grow floor show the results of months of dedicated cultivation, and patients can expect consistent, high-quality flower from both indoor and outdoor crops this year.

- Preparing for the Fall Harvest

September 12, 2021

As September progresses, Flower Factory is entering the pre-harvest phase. Plants in our greenhouses are maturing, showing promising bud development and cannabinoid profiles.

The team is fine-tuning nutrient schedules and monitoring environmental factors, including humidity and airflow, to ensure a clean, consistent growth cycle. Training techniques like low-stress pruning and branch support are being implemented to optimize plant structure.

By carefully tracking plant development, we’re setting the stage for a strong and healthy harvest in October.

- Mid-Summer Growth Updates

August 15, 2021

Flower Factory’s indoor and outdoor crops are thriving as we enter the peak of summer growth. Plants in both greenhouses are showing strong development, with healthy leaves and sturdy stems.

Our team is monitoring irrigation, nutrient schedules, and temperature closely to ensure optimal plant health. Regular inspections and adjustments keep growth consistent and prepare the plants for a successful fall harvest.

We’re also experimenting with pruning and light strategies to maximize yield while maintaining quality. Stay tuned for updates as we approach the final stages before harvest.

- Mid-Summer Harvest Preparations

July 10, 2021

As mid-summer approaches, Flower Factory is preparing for our first major harvest of the season. The indoor expansion and greenhouses are operating at full capacity, and our team is focused on careful trimming, pruning, and monitoring to maximize yield.

We’re excited to see the results of months of careful cultivation, and lab testing will confirm potency and quality for every batch. Patients can expect high-quality flower from both indoor and outdoor crops this year.

- Early Summer Growth Updates

June 15, 2021

The summer growth cycle is underway! Plants in both our indoor and outdoor facilities are thriving, showing excellent health and vigor.

We’ve been closely monitoring irrigation, temperature, and nutrient levels to maintain optimal conditions. The combination of indoor expansion and our new greenhouses allows Flower Factory to produce more flower than ever, while still ensuring quality and consistency for patients.

- Greenhouse Purchase Expands Outdoor Capabilities

May 18, 2021

Flower Factory has officially expanded outdoors! This month we purchased a second greenhouse, bringing our total to two, allowing us to cultivate a larger outdoor crop this season.

The additional greenhouse provides more controlled conditions for outdoor growth, protecting plants from extreme weather while giving us the flexibility to experiment with new strains. Our team is thrilled to begin the summer cycle and share updates from both our indoor and outdoor facilities.

- Electrical Upgrade for Expanded Space

April 12, 2021

Big news this month: Flower Factory completed a major electrical upgrade, increasing our indoor grow capacity by 50%! This expansion allows us to cultivate more plants simultaneously while maintaining perfect environmental controls.

Our team has carefully planned the new layout to maximize light efficiency, airflow, and plant health. With this upgrade, we’re excited to increase production, test new hybrid strains, and continue supplying high-quality medical marijuana to Oklahoma dispensaries.

- Spring Prep: Planning for Expanded Growth

March 15, 2021

Spring is around the corner, and Flower Factory is preparing to expand operations. We’re analyzing growth data from last year to optimize yields and experimenting with new nutrient schedules for several hybrid strains.

With our team’s expertise and attention to detail, we’re confident this year’s harvests will surpass expectations. Stay tuned for updates on our expansion efforts and the first signs of spring growth in our indoor facilities.

- Winter Maintenance and Indoor Upgrades

February 12, 2021

February has been a month of maintenance and preparation. We’ve conducted thorough inspections of our indoor facilities, ensuring lights, climate controls, and irrigation systems are running optimally.

In addition, we’re implementing small upgrades to improve efficiency and plant health. The Flower Factory team is committed to maximizing yield while maintaining our strict quality standards, setting the stage for a productive year ahead.

- Kicking Off 2021 with Continued Growth

January 10, 2021

Flower Factory is starting the year strong! Our team is reviewing past harvests and planning new strategies to continue producing high-quality medical marijuana.

This month, we’re focusing on refining our indoor grow cycles, updating nutrient schedules, and preparing new hybrid strains for the upcoming winter harvest. Patient wellness and consistency remain our top priorities, and we’re excited to share more behind-the-scenes updates as the year progresses.

- Wrapping Up 2020: A Year of Growth

December 15, 2020

2020 has been a milestone year for Flower Factory. Despite the challenges of the past months, our Oklahoma cultivation team has grown stronger, refining techniques, expanding our knowledge, and delivering consistent, high-quality medical marijuana to dispensaries across the state.

This year, we’ve introduced new hybrid strains, optimized indoor grow cycles, and maintained strict lab testing protocols to ensure every batch meets the highest standards of potency, purity, and safety. Our commitment to sustainability and patient care has guided every decision we’ve made.

Looking ahead to 2021, Flower Factory has exciting plans for expanded harvests, additional strains, and even deeper insights into cultivation techniques. We’re grateful to our patients and partners for their continued support and look forward to another year of growth and innovation.